How Aluminum Foundry expertise ensures high-quality results

Wiki Article

Discovering the Diverse Applications and Advantages of Aluminum Foundry in Modern Manufacturing

Aluminum foundries are crucial in today's production landscape. They create elements that serve different markets, consisting of vehicle and aerospace. The lightweight nature of Aluminum combined with its sturdiness makes it a favored option. In addition, ingenious spreading strategies enhance production efficiency. Nonetheless, the implications of these developments on sustainability and future fads necessitate more expedition. What possibilities and obstacles exist ahead for Aluminum foundries in this progressing market?The Duty of Aluminum Foundries in Modern Production

Aluminum shops play a necessary role in contemporary production, adding substantially to different sectors such as auto, aerospace, and construction. These facilities focus on the melting and casting of aluminum, a light-weight, resilient product recognized for its superb deterioration resistance and thermal conductivity. The factories make use of sophisticated methods, consisting of sand spreading, die spreading, and financial investment casting, to create high-quality parts tailored to specific applications.Secret Applications of Aluminum Parts Across Industries

Throughout different markets, Aluminum parts are indispensable to enhancing effectiveness and performance. In the vehicle industry, Aluminum is extensively made use of for engine blocks, transmission instances, and architectural components, contributing to lighter lorries that boost fuel performance. The aerospace market relies on Aluminum for aircraft frameworks, components, and wings, capitalizing on its high strength-to-weight ratio to enhance flight performance.In electronics, Aluminum is made use of in warm sinks and coverings, giving efficient thermal monitoring while maintaining light-weight features (Wisconsin Aluminum Foundry). The building and construction market advantages from Aluminum in home window frameworks, roofing, and cladding, where resilience and appearances are crucial

In addition, packaging applications make use of Aluminum for aluminum foils and cans, giving an effective obstacle versus wetness and light. In each of these sectors, Aluminum parts not only support practical requirements yet additionally promote sustainability with recyclability, making them a favored selection in modern manufacturing techniques.

Benefits of Aluminum Contrasted to Other Products

The adaptability of Aluminum makes it a remarkable choice over many various other products in producing applications. Among its key advantages is its light-weight nature, which adds to lowered energy intake and boosted effectiveness in transportation and building and construction fields. Furthermore, Aluminum exhibits excellent rust resistance, enhancing the durability of items without the need for comprehensive upkeep.In addition, aluminum's pliability permits complex designs and shapes, dealing with diverse sector needs, from automotive to aerospace. Its thermal and electrical conductivity additionally surpasses that of lots of choices, making it optimal for applications needing heat dissipation or electric transmission.

Aluminum is highly recyclable, promoting sustainability in making procedures. Contrasted to steel, it supplies a beneficial strength-to-weight proportion, allowing for robust yet lightweight structures. Jointly, these features position Aluminum as a preferred material, enabling producers to achieve both performance and sustainability in their items.

Cutting-edge Casting Techniques in Aluminum Foundries

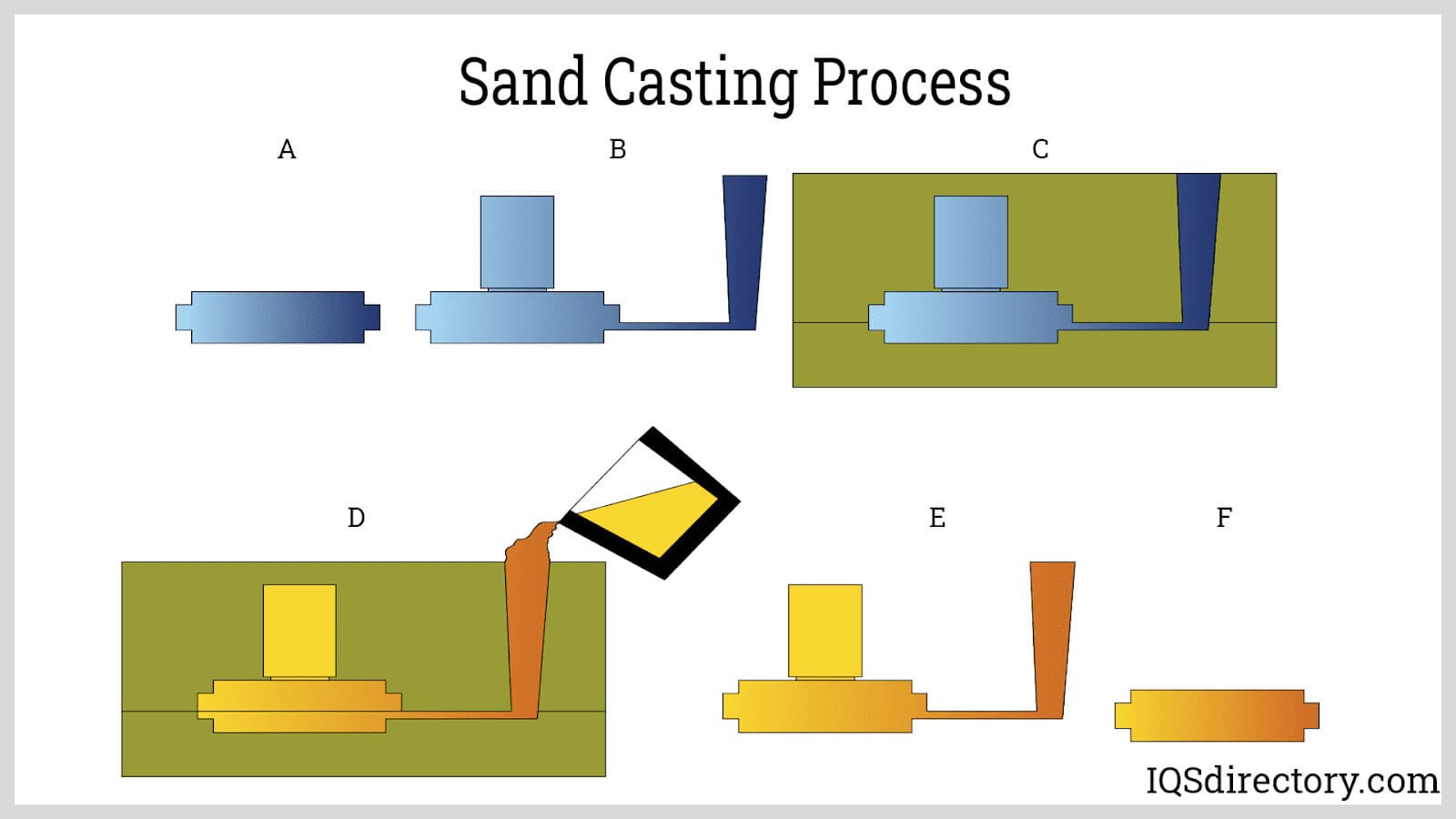

In the domain of Aluminum manufacturing, ingenious casting techniques are transforming the production process and boosting the material's applications. Among these strategies, pass away casting sticks out for its capacity to create intricate shapes with high accuracy and marginal waste. This approach enables quick automation, making it excellent for industries such as automobile and electronics. Investment casting has actually gained popularity due to its capability to create elaborate layouts with superb surface area finish, suiting both huge and tiny elements.An additional remarkable technique is sand spreading, which provides versatility and cost-effectiveness for generating majorities. Recent developments in 3D printing modern technologies are also being incorporated into Aluminum casting, allowing fast prototyping and personalization. These innovations not only boost efficiency yet likewise broaden the opportunities for Aluminum applications across numerous markets, eventually driving the development of modern manufacturing methods.

Sustainability Efforts in Aluminum Manufacturing

Sustainability efforts in Aluminum production concentrate on improving recycling processes, which significantly lower energy intake and exhausts. Carrying out energy performance techniques better adds to a minimized carbon footprint, making Aluminum a more eco-friendly product. These efforts mirror the market's dedication to lasting production and source preservation.Recycling Aluminum Perks

While Aluminum production is resource-intensive, reusing Aluminum offers substantial address benefits that align with sustainability campaigns in manufacturing. Recycling Aluminum requires only 5% of the power required for key production, significantly reducing greenhouse gas discharges. This power efficiency not just conserves natural deposits however additionally lessens the environmental impact related to mining and refining resources. Furthermore, recycling Aluminum supports a circular economy by reestablishing materials back into the supply chain, therefore decreasing waste and promoting source conservation. The procedure likewise produces financial benefits via job creation in reusing centers and minimizes dependence on international Aluminum resources. Generally, recycling Aluminum is an important part of sustainable practices that add to a more environmentally liable production landscape.Energy Effectiveness Practices

The Aluminum manufacturing industry is significantly embracing power effectiveness methods to boost sustainability together with recycling initiatives. These efforts concentrate on optimizing energy consumption throughout the production process. Manufacturers are applying advanced innovations such as high-efficiency heaters and clever grid systems, which enable better power management and decreased waste. Additionally, the integration of eco-friendly energy sources, like solar and wind power, is coming to be extra widespread, moreover reducing dependence on fossil gas. Continuous surveillance and analysis of energy usage help with the recognition of inefficiencies and opportunities for enhancement. Additionally, labor force training on energy-saving techniques guarantees that employees actively add to power conservation initiatives, creating a society of sustainability within the organization. These methods collectively sustain a more sustainable Aluminum production landscape.Decreased Carbon Impact

To accomplish a lower carbon impact, the Aluminum production market is significantly embracing ingenious sustainability efforts. Firms are buying sophisticated technologies that lessen energy consumption and emissions throughout the production process. The assimilation of renewable resource resources, such as solar and wind power, plays an essential duty in reducing reliance on fossil fuels. Additionally, the helpful hints recycling of Aluminum scrap substantially reduces the carbon impact, as recycled Aluminum calls for just a portion of the power needed for key production. Collective efforts among suppliers, governments, and environmental organizations further drive progress in sustainability. By adopting these steps, the Aluminum sector not just addresses ecological worries but also enhances its affordable edge in a market increasingly concentrated on eco-friendly methods.Future Fads in Aluminum Foundry Innovation

Advancement goes to the center of Aluminum Foundry modern technology, reshaping and driving significant advancements market methods. Arising trends consist of the combination of artificial knowledge and artificial intelligence, enhancing procedure optimization and quality assurance. These modern technologies assist in predictive upkeep, minimizing downtime and enhancing functional effectiveness. In addition, using 3D printing and additive production is obtaining grip, permitting for intricate geometries and decreased product waste.Sustainability stays an essential focus, with my response advancements in recycling techniques enhancing the circular economy of aluminum. Companies are significantly embracing energy-efficient approaches, such as low-pressure die casting, which decrease energy consumption and emissions. Moreover, digital twins are coming to be commonplace, enabling real-time monitoring and simulation of Foundry processes.

Frequently Asked Concerns

What Safety and security Actions Remain In Place at Aluminum Foundries?

Aluminum foundries implement different precaution, including protective gear, appropriate ventilation, fire prevention systems, routine safety training, and emergency methods to reduce risks connected with heats, liquified steel handling, and potential exposure to harmful materials.Exactly How Do Aluminum Foundries Make Certain Quality Control Throughout Manufacturing?

Aluminum factories apply rigid quality assurance measures such as regular examinations, material screening, and adherence to industry criteria. These protocols assure consistency in items while minimizing problems, inevitably enhancing the dependability and performance of Aluminum parts.What Are the Typical Obstacles Encountered by Aluminum Foundries?

Aluminum shops frequently encounter obstacles such as preserving regular quality, handling production prices, guiding governing compliance, resolving equipment upkeep concerns, and adjusting to fluctuating market needs, every one of which can influence functional efficiency and productivity. - Metal CastingsJust how Does the Aluminum Recycling Process Work in Foundries?

The Aluminum reusing procedure in foundries includes collecting scrap light weight aluminum, melting it in heaters, eliminating pollutants, and casting the molten steel into preferred shapes, thus reestablishing it right into the production cycle properly and sustainably.What Are the Task Opportunities Available in Aluminum Foundries?

Job opportunities in Aluminum factories consist of duties such as Foundry drivers, quality assurance examiners, maintenance professionals, designers, and production managers. These placements require various ability levels, using possible for occupation advancement within the manufacturing sector.Sustainability efforts in Aluminum manufacturing emphasis on boosting reusing processes, which substantially lower power consumption and exhausts. While Aluminum manufacturing is resource-intensive, reusing Aluminum presents significant advantages that align with sustainability initiatives in manufacturing. Reusing Aluminum calls for just 5% of the power needed for main manufacturing, substantially minimizing greenhouse gas discharges. The Aluminum manufacturing industry is significantly adopting power performance methods to improve sustainability alongside reusing efforts. In addition, the recycling of Aluminum scrap considerably decreases the carbon footprint, as recycled Aluminum calls for only a portion of the energy needed for primary manufacturing.

Report this wiki page